Direct manufacturing of smart structures

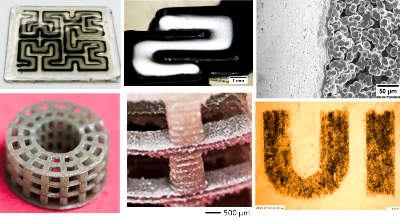

Few of AM technologies are able to fabricate multiple materials and composites, yet they are limited to one class of materials (polymer or metal). To close the gap of multi-classes material additive manufacturing with controlled dispersion patterns, we are examining novel field-assisted additive manufacturing processes, with the goal of printing multi-classes materials with controlled dispersion patterns. Such multi-material AM technology could be used to fabricate smart materials/structures directly from digital models.

Bridging Nano- to Macro-: Multi-Scale Additive Manufacturing

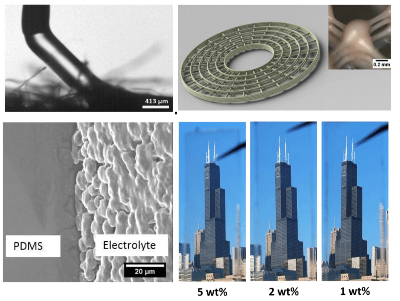

In a typical Additive Manufacturing system, it is critical to make a trade-off between the resolution and build area for applications in which varied dimensional sizes, feature sizes, and accuracy are desired. We are investigating novel AM systems with dynamic resolution control and build size control, with the goal of bridging micro- or even nano-AM to meso- or even macro-AM without sacrificing the build speed.

Novel Direct Ink Writing: High Throughput, High Resolution, Super Rough Substrate

Through introducing external fields and precise temperature control, we are able to innovate the Direct Ink Writing (DIW) process to unlock speed restriction while significantly expanding versatility and substrate choices. Compared to the state-of-the-art DIW processes, our new direct ink writing technology shows orders of magnitude faster direct writing speed (>0.5 m/s), capability of printing on super rough surfaces which were impossible before, capability of printing within confinements, and higher interface strength in multi-material printing.

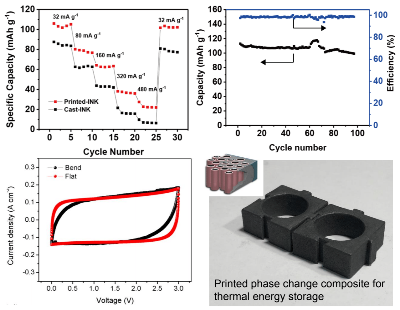

Additive Manufacturing of Energy Components

Additive Manufacturing of Energy Components

We are improving various existing Additive Manufacturing technologies or developing novel manufacturing methods, including direct ink writing, selective laser sintering, and stereolithography, for innovative applications in thermal energy storage, next generation batteries, super capacitors, and flexible electronics.

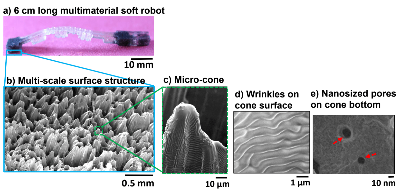

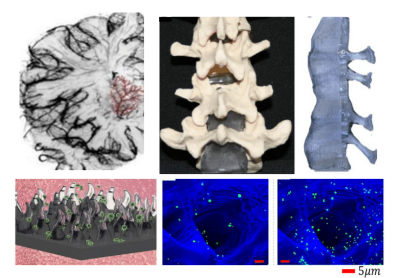

Additive Manufacturing of Biomedical Components

Additive Manufacturing of Biomedical Components

Each year, more than 100 million animals are killed in U.S. for experimentation purpose. Despite its ethical issue and super high expense, the drug dispersion mechanisms learned from animals rarely translated to humans. We are exploring direct digital manufacturing of anatomically accurate, physiological functional physical models for in vitro experiments and bio-compatible soft robots for future biomedical applications.

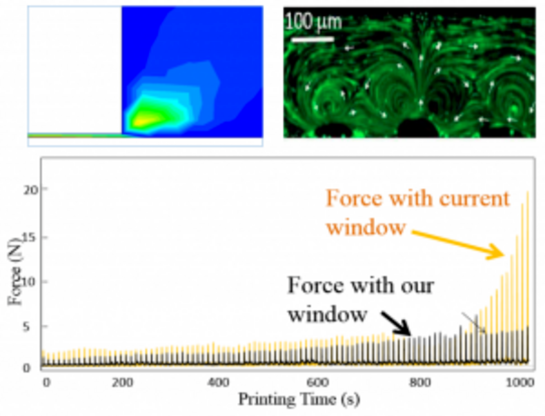

Printing Large Solid Structure in Seconds: Continuous Additive Manufacturing

How to make 3D Printing a real RAPID manufacturing technology? In current AM systems, processing speed and part quality are critical challenges for producing parts with relatively wide solid cross sections. We are exploring continuous projection Stereolithography process (DLP 3D Printing) through liquid-gel-solid multi-phase modeling, highly oxygen window design, gradient light delivery planning, to reduce separation force and liquid filling time significantly, which will finally result in ultra-rapid manufacturing of products with any SOLID geometries and sizes.

Previous Projects

Previous Projects:

-Manufacturing Capability:

- Smooth Surface Fabrication in Mask Projection based Stereolithography

- Multitool and Multi-Axis Computer Numerically Controlled Accummulation for Fabricating Conformal Features on Curved Surfaces

- An Integrated CNC Accumulation System for Automatic Building-Around-Inserts

-Cost Effective:

- A Low-cost Parallel Kinematic Machine for Multidirectional Additive Manufacturing

-Time Efficient:

- A Fast Mask Projection Stereolithography Process for Fabricating Digital Models in Minutes

- Fast Micro-Stereolithography Process based on Bottom-up Projection for Complex Geometry